On-Trend in Operations This Peak Season

Here we are, back again to another calendar fourth quarter and maybe the same for your business. But whether your fiscal calendar lines up or not, it is that most wonderful time of year we all know as peak season.

Each year's a little different, especially lately. But rather than re-hash what we have all lived through leading up to this season, it feels right to have a look at what operations — maybe yours included, are doing to make peak season 2023 a success.

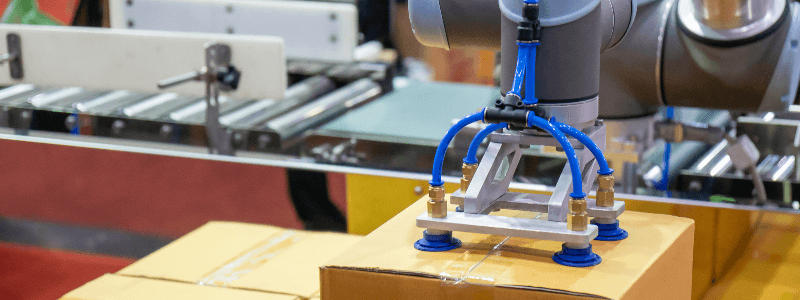

Deploying robots

While talked about for years, the “cobots” or autonomous mobile robots (AMRs) are an emerging presence across the supply chain. Most commonly, AMRs are being deployed to perform repetitive tasks and reduce the time human workers spend toting materials across warehouse floors.

But AMRs can't work alone. The human worker is at the heart of supply chain operations, as evidenced by dual investments from one of the world’s largest parcel delivery firms. Their announcement to hire more than 100,000 seasonal employees balances their investment in autonomous robots for handling repetitive tasks.

Smart inventory management

Each year, historical data and trends can determine what the hot items will be for holiday shoppers. Goods landing on store shelves in November might have begun on a factory line in May, or even last November. And this doesn’t consider the hot holiday gifts inspired by a trendy show, movie or other pop culture movements.

Unlike last year, where retailers found themselves either in stockout or an overabundance thanks to supply chain disruptions, many this year plan to run lean on inventory. The goal, of course, is to balance the risk of stockouts while limiting the deep or extended discounting.

No secret that accurate, real-time inventory visibility is essential to keeping replenishment matched with demand —whether at the distribution center or on the retail floor.

Mitigating returns

The final phase of the peak season cycle is returns. Online shopping convenience can also contribute to the reverselogistics pain retailers and consumer brands feel. Here in the United States, 16.5% of online purchases are returned. Returns rates may vary in your region, but likely correlate with the US average.

As suppliers, we can’t easily compensate for all consumer preferences and behaviors, such as the online shopper who purchases an item in three sizes to select the best fit and return the others. However, suppliers are working hard to reduce mis-picks and other shipping errors that contribute to their future returns. Voice-directed apps on our Velocity platform help supply chain organizations deter these issues.

There is so much happening within our supply chain industry, not to mention the outside pressures placed on it. As you’re navigating this annual marathon, remember to watch your operations for potential bottlenecks or process improvements. If you’re looking for help, consider a process consultation with your supply chain mobility partner. Now is the time to start building your list for peak season 2024 success.