Advanced manufacturing startup Orbital Composites is expanding its in-space servicing, assembly and manufacturing development work with three new Small Business Innovation Research (SBIR) contracts valued at more than $3 million combined.

One contract, for the U.S. Space Force (USSF), is focused on developing a new type of antenna based on an emerging field called “quantum field theory,” that has promising applications for defense customers and in the energy sector. The second, also for the USSF, is looking at developing and printing low-cost CubeSats engineered to withstand harsh radiation environments, such as in geosynchronous orbit (GEO). The final SBIR, with the Air Force, is focused on developing composite printing techniques using an advanced material called “carbon-carbon.”

The three SBIRs reflect Orbital Composite’s deepening commitment to the space industry, to which CEO Amolak Badesha said the company had taken an “unconventional path.”

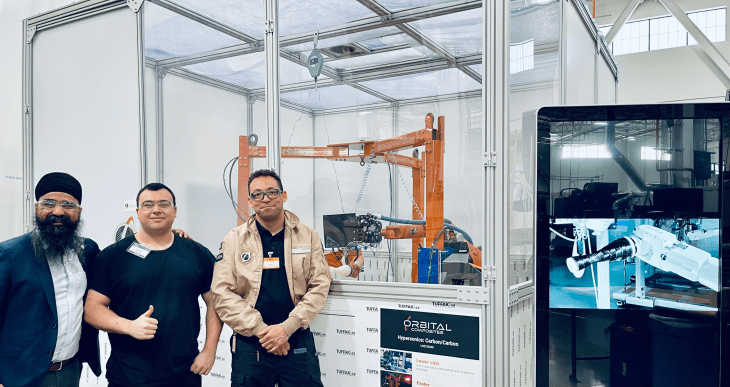

Founded in 2015, Orbital Composites was built on the premise that you could innovate additive manufacturing techniques to print the most advanced products possible. To that end, the company makes robotic printing systems that print composites at varying scales: all the way from the very small and intricate up to the very large.

The company’s manufacturing techniques could be used for industries ranging from space to energy or climate, Badesha explained.

“We’re not dependent on just one market,” he said. “The same materials that are used for reentry vehicles or even for hypersonics, those same materials are used in hydrogen propulsion or even normal commercial aircraft.”

Over time, the company started thinking not just about printing materials for space — but printing them in space, too.

The company has a three-step plan, Badesha said. The first step is making everything on Earth and launching it to space. Step two is printing products, like antenna tiles, on the ground and assembling them in space. “We can start making 15-, 20-meter antennas like that,” he said, at a dramatically reduced cost.

The third step is doing everything in space: printing and assembly.

Skipping terrestrial printing and launch would be a huge cost saver over the long run. Badesha pointed out that antennas are among the biggest points of failure for satellites in GEO. The recent issues with ViaSat’s ViaSat-3 Americas satellite antenna are a case in point: If the company has to claim the mission as a loss, it would be a $700 million failure. In the future, Orbital Composites could have a business either servicing these ultra-expensive antennae or replacing them altogether.

The SBIRs are related to this larger plan. The SBIR contract focused on quantum field antennas is looking at building massive antennas in space — up to kilometer-scale in the case of space-based solar power applications, Badesha said.

“The only way to do that is ISAM — in-space servicing, assembly and manufacturing,” he said.

Last month, Orbital Composites was also awarded a $1.7 million contract from the USSF to work with partners Axiom Space, Northrop Grumman and the Southwest Research Institute to explore 3D printing massive antennas in space. Eventually, the aim is to establish an in-space servicing, assembly and manufacturing lab outside Axiom’s private space station later this decade.